Note: This guest post is by Lewis O’Leary, who has served as both a forensic investigator and restoration contractor since Hurricane Camille (1969). He has a degree in the fields of Mechanical Engineering and Architecture, is a “Building Envelope Consultant, Level 2, licensed by the Building Envelope Science Institute, a “HAAG Certified Inspector – Wind”, is a North Carolina Licensed Public Adjuster, and is a design/build, General Contractor licensed in North Carolina. Mr. O’Leary also serves as a consultant for engineering firms involved with wind damage from hurricanes and tornadoes. He can be contacted at 919-219-4099 or via e-mail at mailto:probuil@aol.com.

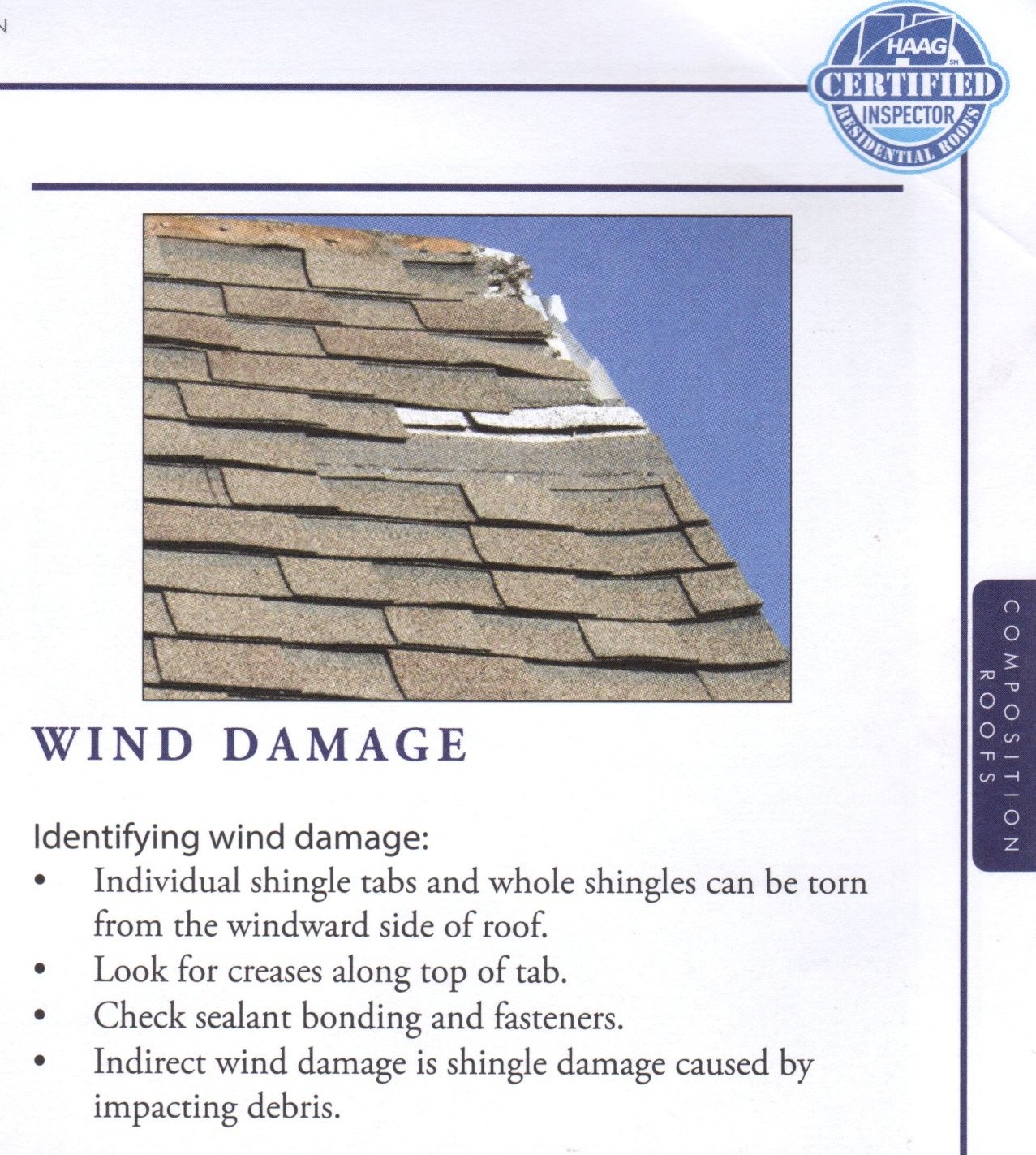

For decades, an important step in investigating wind damage to shingles was to “check sealant bonding and fasteners” (as set out in the above picture, which is shown on page 59 of the “HAAG Certified Inspector – Residential Roofs” Manual).

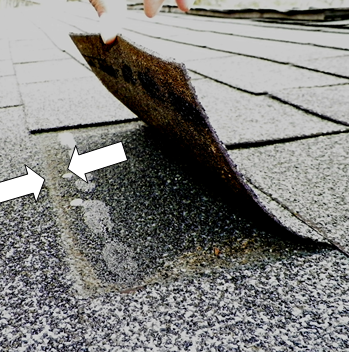

The conventional approach for decades was to conduct what is called the “1-finger test,” as shown in the picture below. The adjacent photo is an example of such. Taking notes from my discussions with the roofing products manufacturers, I further defined this process by setting out the notion that if you want to check seal strip performance, you should do so under the “worst-case” condition (the conventional approach when testing the performance of an item). To accomplish this for shingles is to test them when they are cold or at least cool, which mimics “storm-like conditions.”

Accepted practice, that violated seal strips that were bonded to the bottom of the overlapping shingle, is wind damage. However, in 2017, HAAG Eng. reversed its position on this and produced the attached paper entitled “Misconceptions of Wind Damage to Asphalt Composition Shingles.”

They now believe that any time a seal strip is violated, the wind will be sufficient to fold the tab back sufficiently to cause a “creased, folded or missing shingle.” Specifically, this paper sets out the following:

A shingle that is simply not adhered and is not creased, folded, torn, or missing is not evidence of wind-caused damage.

They state that with newer, very pliable shingles, the crease may be difficult to see, but putting your hand under the shingle may help to find it. A fundamental error in their logic is that if a crease is created, it will be at the nail line, which in this example is a little over 1” up slope from the lower edge of the shingle (see the distance between the two white arrows in the picture above).

That distance is transposed to the photo above, where these white arrows correspond to those on page one. Simply put, the initial natural fold line (aka the pivot point) will form under the overlapping shingle, which is hidden from view. As the wind speed increases, a second crease will form where the lap between these two shingles. HAAG included their test stand in their paper to prove this. However, they did not reveal the wind speed they used in their test.

Earlier this year, I attended the online, 5-year renewal for the “HAAG Certified Inspector – Wind” I was presented with the actual video of the “laboratory testing” they conducted. The two pictures that the blue arrow below is pointing to are photos taken from that video.

Note that the wind speed shown in the insert and the enlarged version is 119 mph. Given that seal strips wind rating is only 60 mph, why would they run the test at 400% of the 3-tabs wind? Based upon a simple understanding of physics, it appears that in order to get the wind force up to enough to create a crease at the lap of the shingles, they had to go up to 119 mph to achieve this.

To assert that the shingle will totally fold over at the same time the 60-mph rated seal strip releases, when their actual test seems to disprove this, it is a problem.

In conclusion, simple physics seems to tell me that the initial crease would occur under the overlap, not at the overlap, where it would be visible. I agree that when the wind speed increases enough, it can cause the shingle to continue to fold over on itself, creating a second crease, which is readily visible when inspecting a roof. However, experience tells me that the vast majority of 3-tab shingles will fail by about 75 mph, which, I have learned over decades of dealing with roofing manufacturers, is not strong enough to fold a very flexible tab over onto itself.

#Addressing #Notion #Failure #Bond #Seal #Strips #Wind #Damage #Shingle #Creased #Torn